Jun 14, 2023The basic type of manufacturing process in mechanical engineering is Machining. It is a controlled material-removal process in which a component (typically metal) is cut to the desired final form and size. Machining is utilised in the production of numerous metal products, but it can also be applied to wood, plastic, ceramic, and composite

Rice Milling Machine by chinaricemachine – Issuu

Alternatively, mechanics may be divided according to the kind of system studied. The simplest mechanical system is the particle, defined as a body so small that its shape and internal structure are of no consequence in the given problem. More complicated is the motion of a system of two or more particles that exert forces on one another and

Source Image: facebook.com

Download Image

These processes are mechanical. The process usually begins in the manufacturing industry with materials processing, which involves the selection of raw materials such as sand, silica, steel, plastics, iron, and so on. The materials undergo a systematic chain of manufacturing processes that includes sophisticated machinery and power tools.

Source Image: linquip.com

Download Image

CH – Chemical Engineering 3 days ago0 meanings: A mechanical device has parts that move when it is working, often using power from an engine…. Click for more definitions.

Source Image: safeworldhse.com

Download Image

Which Of The Following Is A Mechanical Process

3 days ago0 meanings: A mechanical device has parts that move when it is working, often using power from an engine…. Click for more definitions. Sep 25, 2023Step 3: Refining the Plan and Beginning the Design Process According to Standards and Procedures. This stage involves executing the confirmed plan and drafting detailed blueprints. During the design refinement process, feasibility, various costs, including manufacturing, procurement, transportation, installation, debugging, electrical control

Manual Material Handling Safety Dos and Don’ts – Safe handling of material – HSE and Fire protection | safety, OHSA, health, environment, process safety, occupational diseases

A mechanical process refers to a process that physically removes or reduces contaminants, rather than using chemical or biological agents. Out of the options provided, cleaning is a mechanical process. Cleaning involves scrubbing, washing, or using mechanical force to remove dirt, dust, or other impurities from a surface. Mechanical blog

Source Image: facebook.com

Download Image

PERFORMANCE Carburetor AIR INTAKE Pipe VELOCITY STACK FOR HONDA CRF300L CRF300 | eBay A mechanical process refers to a process that physically removes or reduces contaminants, rather than using chemical or biological agents. Out of the options provided, cleaning is a mechanical process. Cleaning involves scrubbing, washing, or using mechanical force to remove dirt, dust, or other impurities from a surface.

Source Image: ebay.ca

Download Image

Rice Milling Machine by chinaricemachine – Issuu Jun 14, 2023The basic type of manufacturing process in mechanical engineering is Machining. It is a controlled material-removal process in which a component (typically metal) is cut to the desired final form and size. Machining is utilised in the production of numerous metal products, but it can also be applied to wood, plastic, ceramic, and composite

Source Image: issuu.com

Download Image

CH – Chemical Engineering These processes are mechanical. The process usually begins in the manufacturing industry with materials processing, which involves the selection of raw materials such as sand, silica, steel, plastics, iron, and so on. The materials undergo a systematic chain of manufacturing processes that includes sophisticated machinery and power tools.

Source Image: m.facebook.com

Download Image

Mechanical Back Off: Basics & Procedures | Drilling Course Design is an innovative and iterative process. It is also a decision-making process. It is a communication-intensive activity in which both words and drawings are employed. Mechanical engineering design involves the design of things and systems of a mechanical nature: machines, products, structures, devices, and instruments. Learning objectives

Source Image: drillingcourse.com

Download Image

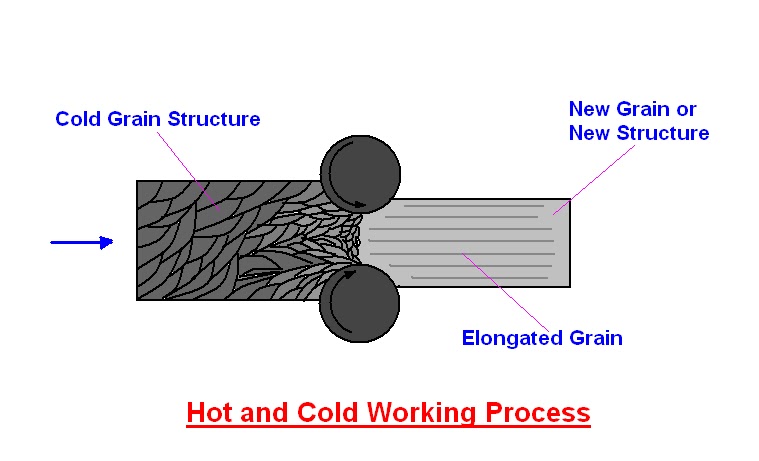

Mechanical Engineering: Hot working and Cold working (Forging, Extrusion, Rolling) 3 days ago0 meanings: A mechanical device has parts that move when it is working, often using power from an engine…. Click for more definitions.

Source Image: mech413.blogspot.com

Download Image

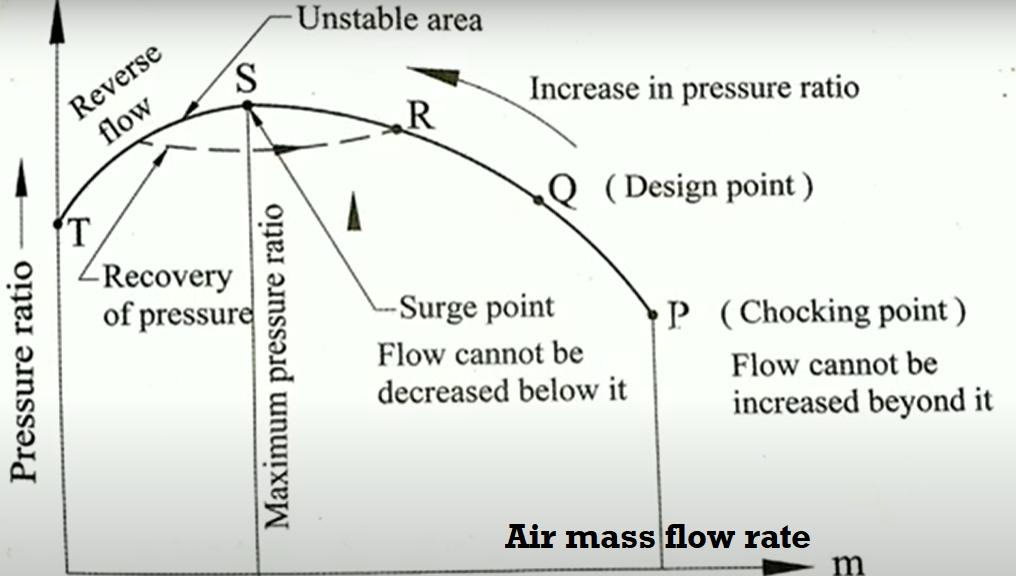

Axial compressor Surge, fouling, and stall phenomena. Sep 25, 2023Step 3: Refining the Plan and Beginning the Design Process According to Standards and Procedures. This stage involves executing the confirmed plan and drafting detailed blueprints. During the design refinement process, feasibility, various costs, including manufacturing, procurement, transportation, installation, debugging, electrical control

Source Image: linkedin.com

Download Image

PERFORMANCE Carburetor AIR INTAKE Pipe VELOCITY STACK FOR HONDA CRF300L CRF300 | eBay

Axial compressor Surge, fouling, and stall phenomena. Alternatively, mechanics may be divided according to the kind of system studied. The simplest mechanical system is the particle, defined as a body so small that its shape and internal structure are of no consequence in the given problem. More complicated is the motion of a system of two or more particles that exert forces on one another and

CH – Chemical Engineering Mechanical Engineering: Hot working and Cold working (Forging, Extrusion, Rolling) Design is an innovative and iterative process. It is also a decision-making process. It is a communication-intensive activity in which both words and drawings are employed. Mechanical engineering design involves the design of things and systems of a mechanical nature: machines, products, structures, devices, and instruments. Learning objectives